Hi all! I am currently working at Apple as a AR/VR Software Engineer on the Application and Content team. With a strong determination and pursuit for turning ideas into reality, I find myself always prepared for a challenge. I strongly believe in giving back to the community in any form through my experiences and skills in effort to make society a better place.

Also, feel free to take a look at my resume to learn more about me! I am currently interested in opportunities involving backend, software infrastructure and application development.

AR/VR Software Engineer

Apple

• Worked on Freeform iOS/visionOS (AR/VR) application using Swift/Objective-C in coalition with HI, QA and design team

• Using front-end principles with SwiftUI and UIKit to create a more seamless UI/UX with Apple’s standards

• Established real-time collaboration layer to allow for simultaneous interactions with other participants using CRDT’s, OT’s and Coherence framework in addition to integration with Apple’s CloudKit service

• Automated log data collection from users using Python to record telemetry results, and track power and performance metrics across the app ecosystem using Splunk dashboard

• Expanded quality and stability of application through unit-testing and building test infrastructure using XCTest framework

Software Engineer

Rivian

• Created backend diagnostic testing service for all vehicle ECU software using Python with functional user interface

• Utilize Jama REST API to extract data and automate test cycling through CAN, LIN, Ethernet, IO and OTA communications

• Optimized CI builds with Jenkins to streamline operations using Kubernetes for containerized applications management

• Assisting software cycling at factory through automating all manual processes throughout vehicle line

• Support PostgreSQL database in AWS for fast and efficient deployments in the cloud

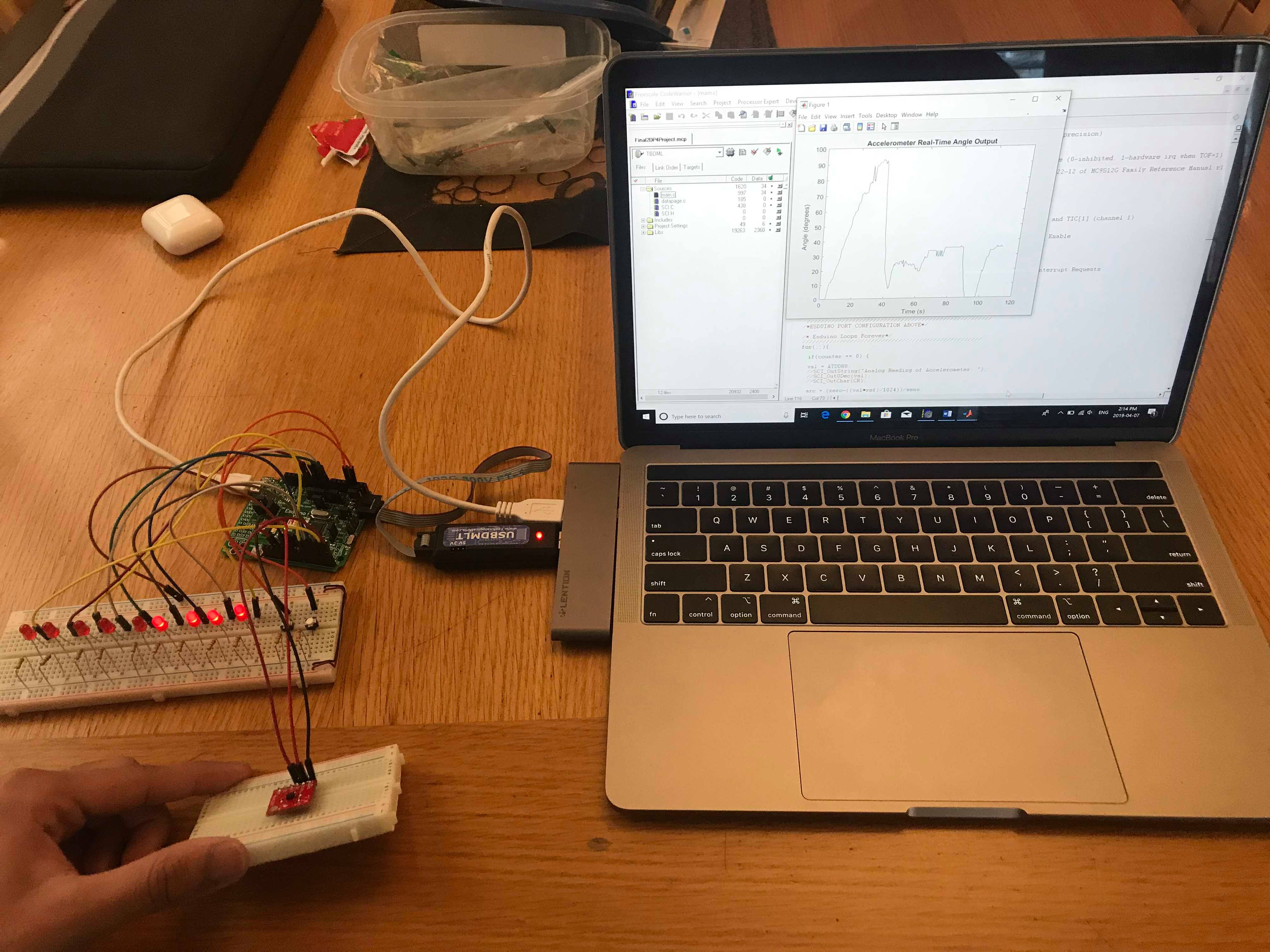

System Integration Intern

Tesla

• Special projects team; electrical and software integration, simulation and modelling to improve vehicle performance, safety, and user experience in future Tesla vehicles

• Created gyropscope system using inertial sensors in order to detect orientation to advance cabin intelligence using Arduino and MATLAB software via I2C/SPI communication protocol

• Testing and validation of RFID detection using sensors for improved handling and communication of vehicle components

• Executed DOE's in order to improve thermal management through energy-efficient HVAC controls

• Strong project management through managing various vendor relationships for several concepts related to future vehicle designs and optimization

Cell Engineering Intern

Tesla

• Designed prototypes for testing alignment and accuracy using laser cutter and 3D printing for mechanical apparatus for micron-level measurements (< 30 microns) using Solidworks

• Created cell simulation using MATLAB to output new potential cell build designs that improve energy efficiency by 2%

• Innovated existing integrated battery systems through automating data collection and statistical analysis using JMP, Python and SQL in server architecture to decrease production lead time

• Contacted and managed external vendor relationships for high-precision cameras, lab equipment, and machine anchoring in upbringing new manufacturing pilot line for battery R&D

• Validated cell designs using microscopes and other metrology inspections

• Performed DOE's and implemented quality control processes to improve the efficiency of battery cells within both automotive and energy products

• Also, a big part of my internship was working on the new battery cell design; ramping up production, quality inspections and electrical testing! A summary of Tesla's battery day highlights can be found here: Battery Day Highlights

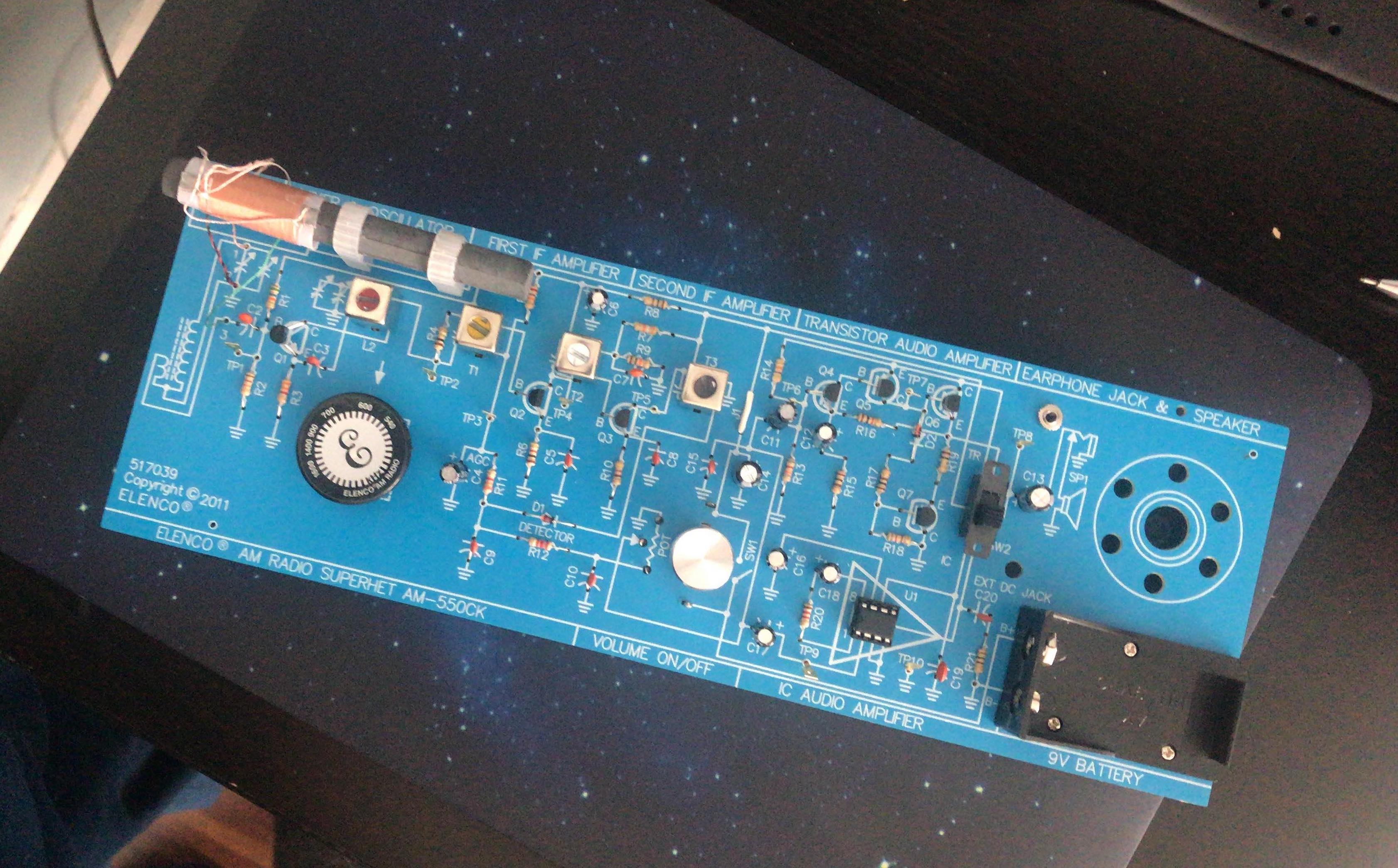

Hardware Research & Development Intern

Eaton

• Hardware testing of innovative smart lighting devices to ensure measured electrical characteristics (ex. rise time, fall time, voltage and current levels) meet DALI protocol

• Designed test systems using oscilloscope, multimeters, DALI bus, transducers and other tools to accurately examine hardware specifications

• Utilized Altium PCB design and created electrical test plans for device circuitry/debugging and schematic capture

• Debug production firmware written in C and develop testing software using LabVIEW for troubleshooting hardware products

• Updated documentation for various hardware devices in accordance with the DALI protocol and engineering standards

Lab Assistant

Center of Mechatronics & Hybrid Technologies

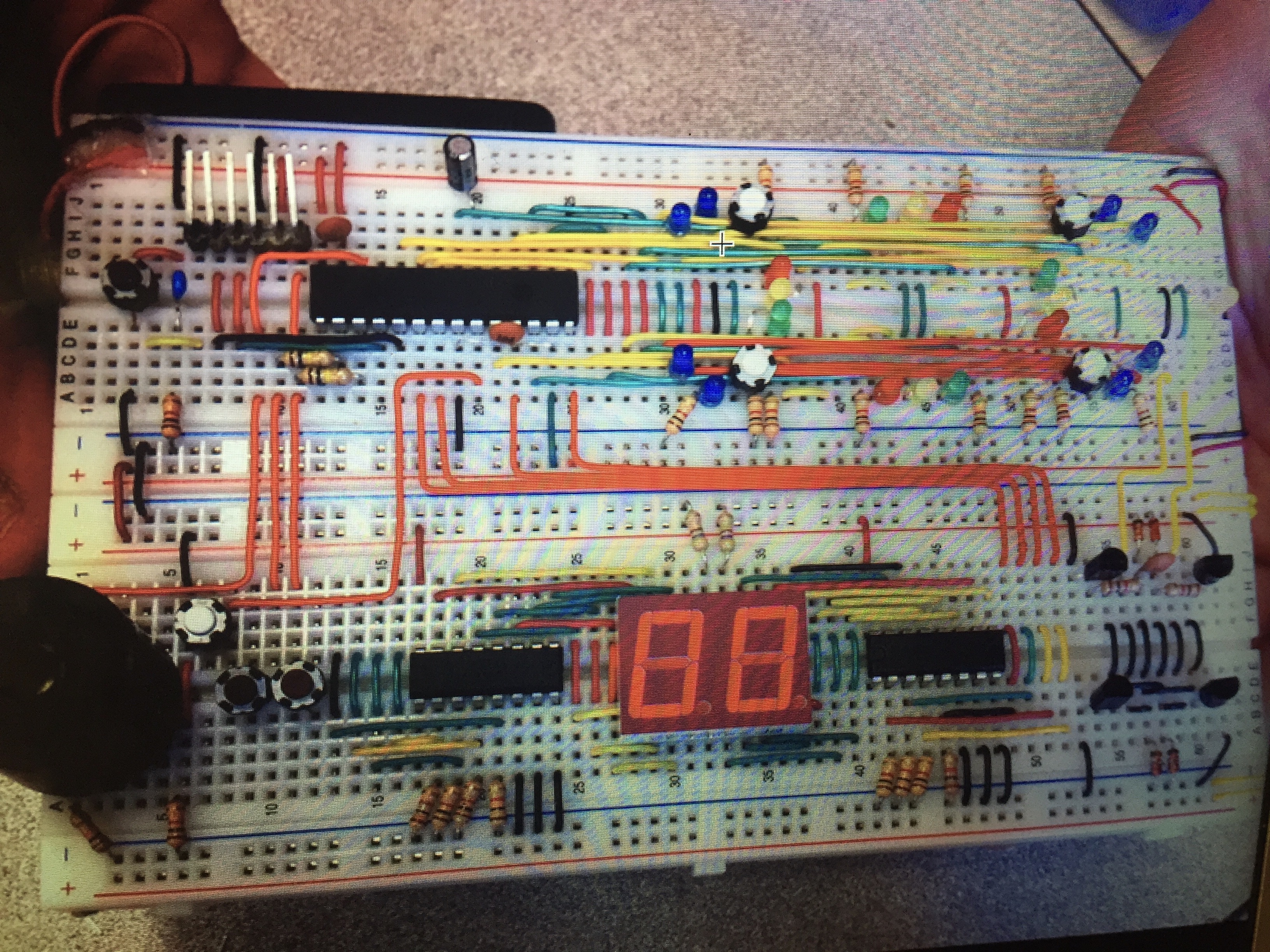

• Utilized PLC’s, HMI’s, and hardware design in the development of embedded prototypes

• Modified an industrial electromechanical control panel using a Siemens PLC module (Simodrive 611) to test multiple high-power servo motors used in EV battery and engine reliability test analysis while interpreting GD&T drawings

• Created wiring diagrams and software tests/scripts using Python to attain measurements and data insight using AutoCAD Electrical and CATIA V5

• Communicated with technical representatives from related companies to meet technical design requirements and gain project insight

Avionics Engineer Intern

PAL Aerospace

• Conducted and managed several aircraft reliability checks such as strain gauge and current transducer testing using RCA and FMEA tactics

• Prepared hardware test fixtures and calibrated lab equipment including low-voltage systems and oscilloscopes using common power tools instrumentation

• Created wiring diagrams, project proposals and embedded software programs using data acquisition systems with AutoCAD Electrical and C/C++

• Abided by the rules and regulations of Transport Canada when troubleshooting, performing and reporting on ground and flight test plans

Production Operations Intern

WestRock

• Assisted the production line with the design and development of merchandising displays through machine operations, automations and assemblies

• Managed orders and all requirements on the company database using SQL in accordance with the safety and health committee

• Several machines used such as the Bobsts, Automatan, and the Masterflex

• Contacted external vendors for quality feedback on products and documented all necessary actions into company database

If you want to chat, see more of my work, or learn more about me, feel free to reach out!